Kaabo si awọn oju opo wẹẹbu wa!

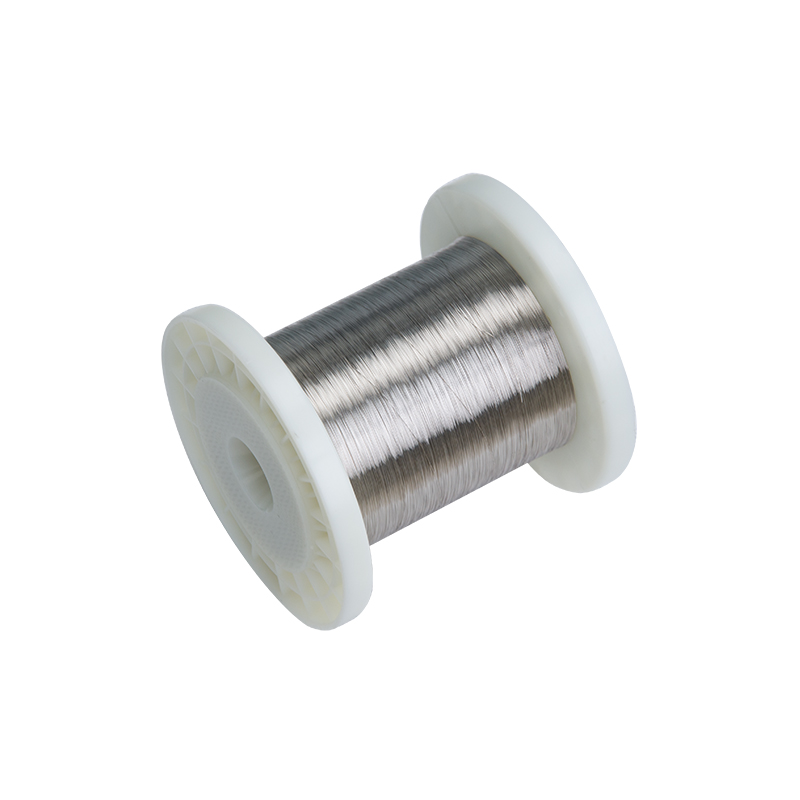

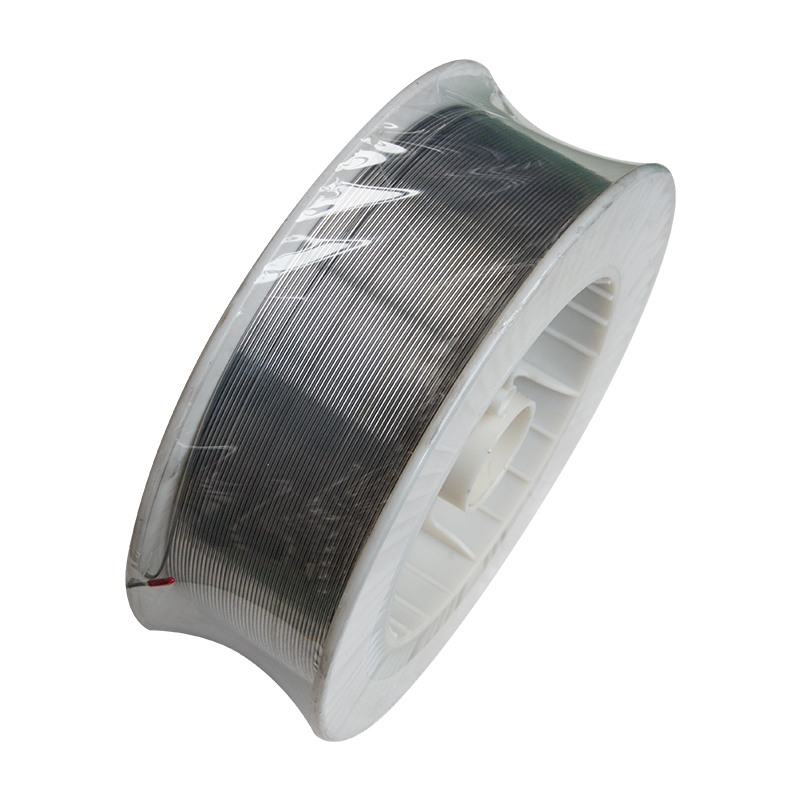

Permalloy E11c Ni79Mo4 79HM Soft Magnetic Alloy Waya

Paramita

TABLE 1 Kemikali ibeere

| Eroja | C≤ | P≤ | S≤ | Mn | Si | Cu≤ | Mo | Ni | Fe |

| Àkópọ̀% | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.3-0.5 | 0.20 | 3.8-4.1 | 78.5-80.0 | Iyokù |

Awọn akọsilẹ:

Apẹrẹ ati awọn iwọn ti awọn alloys wa ni ibamu pẹlu GBn198-88

TABLE 2 Ibeere ti ara

| Ohun ini | Isọdọtun (μΩM) | Desinty(g/cm3) | Curie Point.C | Ikunrere giga magneto-striction coeffientλθ/10-6 |

| Iye | 0.55 | 8.6 | 450 | 2 |

TABLE 3 Awọn ohun-ini oofa AC fun Rinkuro (Iye min)

| Sisanra | Oke fun agbara aaye oofa jẹ 0.1A/m,Labẹ oriṣiriṣi eefin eefa ti o ni irọrun μm/(mH/m) | |||

| 60Hz | 400Hz | 1 KHz | 10 KHz | |

| 0.02 | 17.5 | 12.5 | ||

| 0.05 | 18.8 | 9.4 | ||

| 0.10 | 22.5 | 15 | ||

| 0.20 | 12.5 | 7.5 | ||

| 0.35 | 25 | 8.8 | ||

TABLE 4 Olusọdipúpọ ti Imugboroosi Linear ni orisirisi awọn iwọn otutu/(x10-6)

| Iwọn otutu | 20-100°C | 20-200ºC | 20-300ºC | 20-400ºC | 20-500ºC | 20-600ºC | 20-700ºC |

| Iye | 1.3-10.8 | 10.9-11.2 | 14.4-12.9 | 11.9-12.5 | 12.3-13.2 | 12.7-13.4 | 13.1-13.6 |

TABLE 5 Ibeere oofa (Ibi yiyi tutu)

Ipele I

| (δ&D)/mm | μ0.08/(mHm)≥ | μm (mHm) ≥ | Bs/T≥ | Hc(A/M)≤ |

| 0.005 | 12.5 | 44.0 | 0.75 | 6.4 |

| 0.01 | 17.5 | 87.5 | 0.75 | 4.8 |

| 0.02-0.04 | 20.0 | 112.5 | 0.75 | 4.0 |

| 0.05-0.09 | 22.5 | 137.5 | 0.75 | 2.8 |

| 0.10-0.19 | 25.0 | 162.5 | 0.75 | 2.0 |

| 0.20-0.34 | 28.0 | 225.0 | 0.75 | 1.6 |

| 0.35-1.00 | 30.0 | 250.0 | 0.75 | 1.2 |

| 1.10-2.50 | 27.5 | 225.0 | 0.75 | 1.6 |

| 2.50-3.00 | 26.3 | 187.5 | 0.75 | 2.0 |

Ipele II

| (δ&D)/mm | μ0.08/(mHm)≥ | μm (mHm) ≥ | Bs/T≥ | Hc(A/M)≤ |

| 0.02-0.04 | 22.5 | 125.0 | 0.75 | 2.4 |

| 0.05-0.09 | 25.0 | 150.0 | 0.75 | 2.0 |

| 0.10-0.19 | 27.5 | 187.5 | 0.75 | 1.6 |

| 0.20-0.34 | 31.3 | 250.0 | 0.75 | 1.2 |

| 0.35 | 32.5 | 275.0 | 0.75 | 0.79 |

Ipele III

| (δ&D)/mm | μ0.08/(mHm)≥ | μm (mHm) ≥ | Bs/T≥ | Hc(A/M)≤ |

| 0.01 | 25.0 | 150.0 | 0.73 | 2.4 |

| 0.02-0.04 | 31.0 | 190.0 | 0.73 | 1.6 |

| 0.05-0.09 | 38.0 | 250.0 | 0.73 | 1.2 |

| 0.10-0.19 | 38.0 | 250.0 | 0.73 | 1.2 |

| 0.20-0.34 | 38.0 | 280.0 | 0.73 | 1.0 |

| 0.35 | 44.0 | 310.0 | 0.73 | 1.0 |

Gbona sẹsẹ (forging) Flastspring

| (δ&D)/mm | μ0.08/(mHm)≥ | μm (mHm) ≥ | Bs/T≥ | Hc(A/M)≤ |

| 3-22 | 25.0 | 125 | 0.75 | 2.4 |

Gbona Yiyi (Forging) Pẹpẹ

| (δ&D)/mm | μ0.08/(mHm)≥ | μm (mHm) ≥ | Bs/T≥ | Hc(A/M)≤ |

| 8-100 | 25.0 | 125.0 | 0.75 | 2.4 |

Kọ ifiranṣẹ rẹ nibi ki o si fi si wa