Wáyà Síńkì/Monel Pípé 400/Tafa 70t/Monel K500/Ernicu-7/Ni95al5/Tafa 75b/Hastalloy C-276 Irin Alagbara Nickel Alloy Thermal Spray Waya

Sinkii mimọ/Moneli 400/Tafa 70t/Monel K500/Ernicu-7/Ni95al5/Tafa 75b/Hastalloy C-276Irin Alagbara, Irin Gbona Sokiri Waya

Àpèjúwe Ọjà

1. FM60 Oxford Alloy 60ERNiCu-7Ọ̀pá ìlùmọ́ra TIG

ERNiCu-7Ó ní agbára tó dára, ó sì ń tako ìbàjẹ́ ní ọ̀pọ̀lọpọ̀ ibi tí ó wà nínú omi òkun, iyọ̀, àti àwọn ohun tí ó ń dínkù nínú acid. A sì lè lò ó láti bo irin erogba mọ́lẹ̀, tí a bá lo ERNi-1 fún ìpele àkọ́kọ́. Alloy yìí kò le gbóná fún ọjọ́ orí, nígbà tí a bá sì lò ó láti so mọ́ Monel K-500, agbára rẹ̀ kéré sí ti irin ìpìlẹ̀.

Àwọn Orúkọ tí a wọ́pọ̀: Oxford Alloy® 60 FM 60 Techalloy 418

Standard: AWS 5.14 Kilasi ERNiCu-7 / ASME SFA 5.14 Kilasi ERNiCu-7 ASME II, SFA-5.14 UNS N04060 Werkstoff Nr. 2.4377 ISO SNi4060 Europe NiCu30Mn3Ti

ÀWỌN KẸ́MÍKÀ(%)

| C | Si | Mn | S | P | Ni |

| ≤0.15 | ≤1.25 | ≤4.0 | ≤0.015 | ≤0.02 | 62-69 |

| Al | Ti | Fe | Cu | awọn miiran | |

| ≤1.25 | 1.5-3.0 | ≤2.5 | Isinmi | <0.5 |

Àwọn ìpele ìfọwọ́sowọ́pọ̀

| Ilana | Iwọn opin | Fọ́ltéèjì | Amperesi | Gáàsì |

| TIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) 3/32″ (2.4mm) 1/8″ (3.2mm) | 12-15 13-16 14-18 15-20 15-20 | 60-90 80-110 90-130 120-175 150-220 | 100% Argon 100% Argon 100% Argon 100% Argon 100% Argon |

| MIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) | 26-29 28-32 29-33 | 150-190 180-220 200-250 | 75% Argon+25% Helium 75% Argon+25% Helium 75% Argon + 25% Helium |

| SAW | 3/32″ (2.4mm) 1/8″ (3.2mm) 5/32″ (4.0mm) | 28-30 29-32 30-33 | 275-350 350-450 400-550 | A le lo Flux ti o yẹ A le lo Flux ti o yẹ A le lo Flux ti o yẹ |

Àwọn OHUN ÈLÒ ÌṢẸ́-Ẹ̀RỌ

| Agbara fifẹ | 76,5000 PSI | 530 MPA |

| Agbára Ìmúṣẹ | 52,500 PSI | 360 MPA |

| Gbigbọn | 34% |

Àwọn ohun èlò ìfilọ́lẹ̀

A le lo ERNiCu-7 fun awọn ohun elo alurinmorin ti o yatọ si ara wọn nipa lilo awọn alloy nickel-copper si nickel 200 ati si awọn alloy copper-nickel.

A nlo ERNiCu-7 fun fifọ gaasi-tungsten-arc, gaasi-metal-arc, ati fifọ arc ti a fi sinu omi ti alloy Monel 400 ati K-500.

A lo ERNiCu-7 pupọ ninu lilo omi nitori pe o ni agbara lati koju ipa ibajẹ ti omi okun ati omi gbigbẹ.

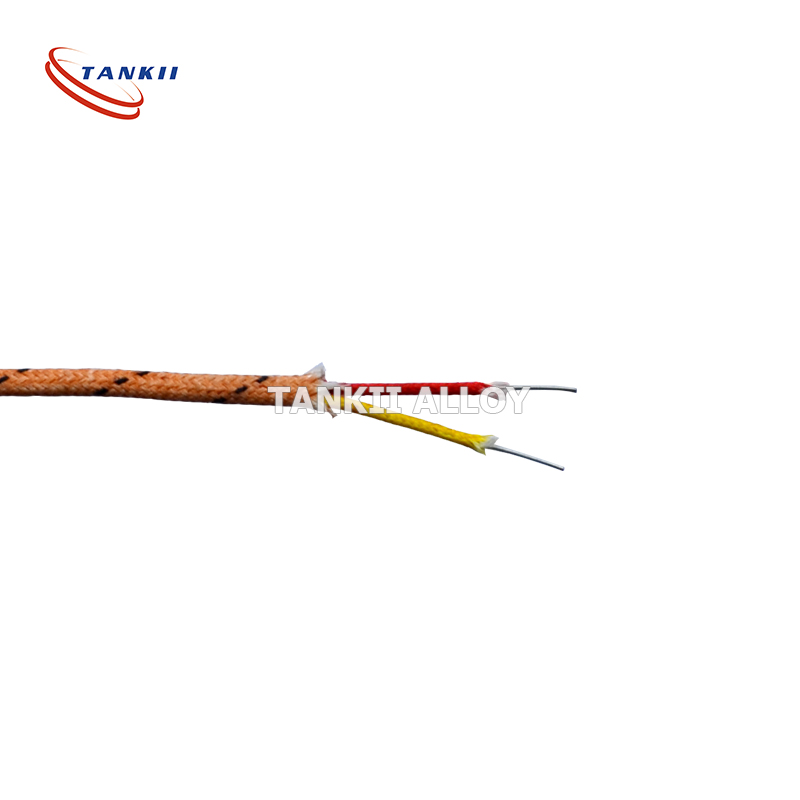

2. Waya Sokiri Gbona Miiran

| Ohun kan | Àkóónú kẹ́míkà | Zn | Cd | Pb | Fe | Cu | Àròpọ̀ Ìwọ̀n Ìwọ̀n |

| sinkii mimọ | Iye olorúkọ | ≥99.995 | ≤0.002 | ≤0.003 | ≤0.002 | ≤0.001 | 0.005 |

| Ohun kan | Inconel 625 | Ni95Al5 | 45CT | Moneli 400 | Moneli 500 | HC-276 | Cr20Ni80 |

| C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

| Fe | ≤1.0 | Kò sí | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | Kò sí |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

| Cu | Kò sí | Kò sí | Kò sí | isinmi | 27-33 | Kò sí | Kò sí |

| Ni | isinmi | isinmi | isinmi | 65-67 | isinmi | isinmi | isinmi |

| Co | Kò sí | Kò sí | Kò sí | Kò sí | Kò sí | Kò sí | Kò sí |

| Al | ≤0.4 | 4-5 | Kò sí | ≤0.5 | 2.3-3.15 | Kò sí | Kò sí |

| Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | Kò sí | Kò sí |

| Cr | 21.5-23 | ≤0.2 | 42-46 | Kò sí | Kò sí | 14.5-16 | 20-23 |

| Nb | 3.5-4.15 | Kò sí | Kò sí | Kò sí | Kò sí | Kò sí | ≤1.0 |

| Mo | 8.5-10 | Kò sí | Kò sí | Kò sí | Kò sí | 15-17 | Kò sí |

| V | Kò sí | Kò sí | Kò sí | Kò sí | Kò sí | ≤0.35 | Kò sí |

| W | Kò sí | Kò sí | Kò sí | Kò sí | Kò sí | 3.0-4.5 | Kò sí |

| Àwọn àìmọ́ | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

3. C276waya sokiri gbona

Àwọn Orúkọ tí a wọ́pọ̀: Oxford Alloy® C-276 FM C-276 Techalloy 276

Standard: AWS A5.14, ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Europe NiCrMo16Fe6W4

ÀWỌN KẸ́MÍKÀ(%)

| C | Si | Mn | S | P | Ni | Co |

| ≤0.02 | ≤0.08 | ≤1.0 | ≤0.03 | ≤0.04 | Isinmi | ≤2.5 |

| W | V | Fe | Cu | Cr | Mo | awọn miiran |

| 3.0-4.5 | ≤0.35 | 4.0-7.0 | ≤0.5 | 14.5-16.5 | 15-17 | <0.5 |

Àwọn ẹ̀ka ọjà

-

Foonu

-

Ìmeeli

-

Whatsapp

-

WeChat

Judi

150 0000 2421

-

Òkè