Kaabo si awọn oju opo wẹẹbu wa!

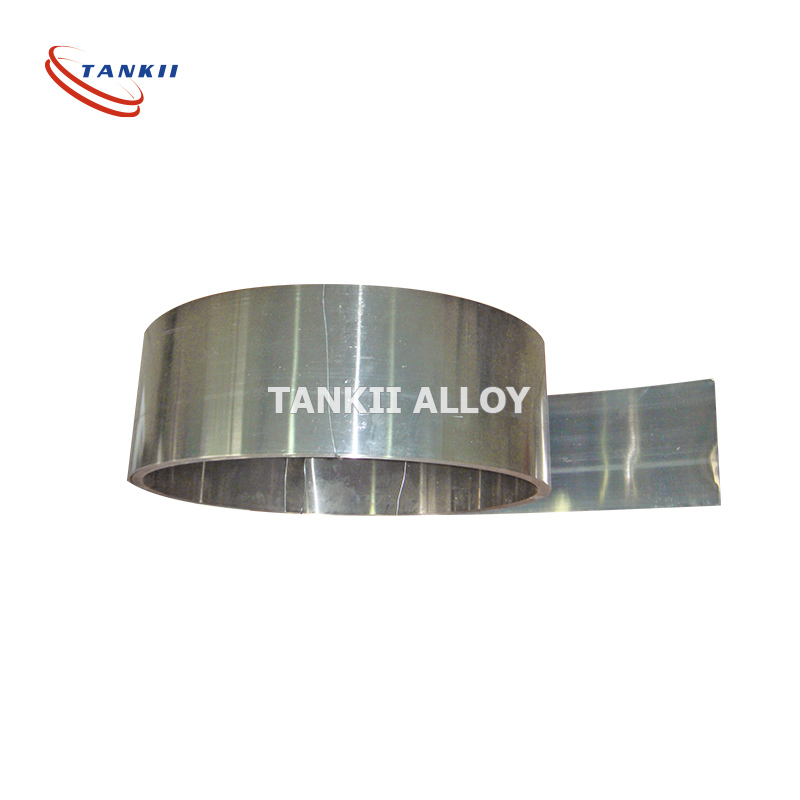

Ìlànà ìdènà alloy Fecral 0Cr15Al5 láti ilé iṣẹ́

Fecral0Cr15Al5Igi resistance alloy nipasẹ ile-iṣẹ

| Ipele | |

| Iwọn | sisanra:0.05-3mm iwọn:4-250mm |

| Ilẹ̀ | fífọ́ tó mọ́lẹ̀ |

| Ìwúwo | 5-200kg/yípo, gẹ́gẹ́ bí iye àwọn oníbàárà |

| Àìfaradà | 1.3±0.05μΩ.m |

| Líle (HV) | 180-210HV |

| Gbigbọn | ≥16% |

| Ipele | Iwọn otutu to ga julọ | Àìfaradà | Líle | Agbara fifẹ | Gbigbọn |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr25Ni20 | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Ipele | Àkójọpọ̀ kẹ́míkà% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | iwontunwonsi |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | iwontunwonsi |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | iwontunwonsi |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | iwontunwonsi | ⼜0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | ⼜0.5 | iwontunwonsi |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | iwontunwonsi |

| Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | iwontunwonsi |

Shanghai Tankii Alloy Material Co., Ltd. fojusi lori iṣelọpọ ti nichrome alloy, thermocouple waya, fecral alloy, precision alloy, copper nickel alloy, thermal spray alloy ati be be lo ni irisi waya, sheet, teepu, strip, rod ati awo.

A ti ni iwe-ẹri eto didara ISO 9001 ati ifọwọsi eto aabo ayika ISO 14001. A ni eto iṣelọpọ ti o ni ilọsiwaju ti isọdọtun, idinku otutu, iyaworan ati itọju ooru ati bẹbẹ lọ. A tun ni agbara iwadii ati idagbasoke ominira.

Kọ ifiranṣẹ rẹ si ibi ki o fi ranṣẹ si wa

Àwọn ẹ̀ka ọjà

-

Foonu

-

Ìmeeli

-

Whatsapp

-

WeChat

Judi

150 0000 2421

-

Òkè