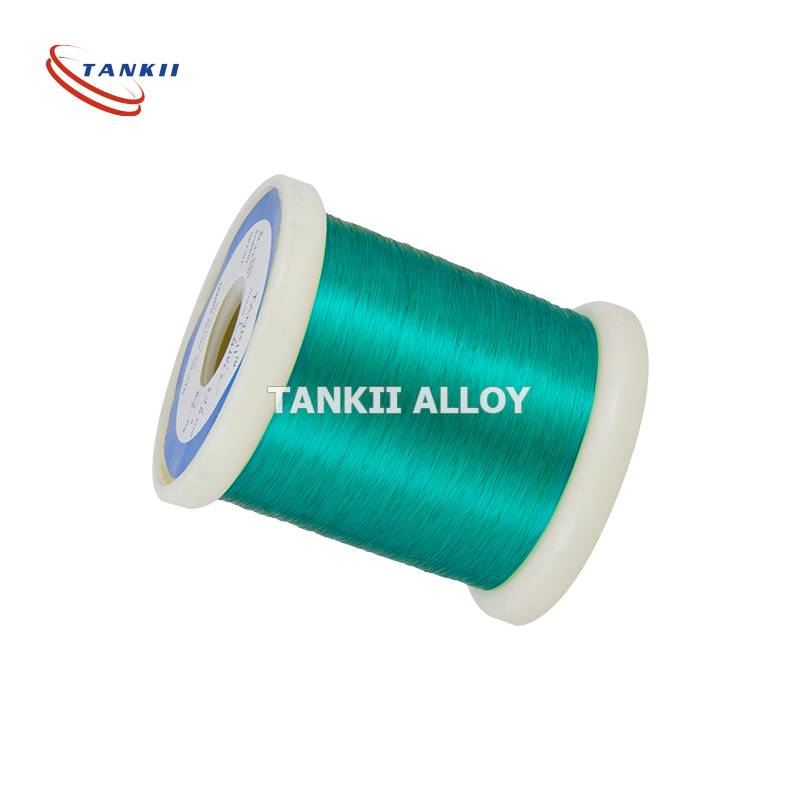

Wáyà bàbà yíká tí a fi ọṣẹ ṣe ní kíláàsì F nylon/polyester tí a yípadà

Kíláàsì Fnaịlọn/yika ti a ti yipada ti a fi enamel ṣe ti polyesterWaya idẹ

Àpèjúwe Ọjà

Àwọn wáyà ìdènà tí a fi enamel ṣe yìí ni a ti lò fún àwọn ìdènà ìdúróṣinṣin, ọkọ̀ ayọ́kẹ́lẹ́

àwọn ẹ̀yà ara, àwọn resistors tí ń yípo, àti bẹ́ẹ̀ bẹ́ẹ̀ lọ nípa líloidaboboìṣiṣẹ́ tó dára jùlọ fún àwọn ohun èlò wọ̀nyí, ní lílo àǹfààní gbogbo àwọn ànímọ́ pàtàkì ti ìbòrí enamel.

Pẹlupẹlu, a yoo ṣe ideri enamelidaboboàwọn wáyà irin iyebíye bíi fàdákà àti wáyà platinum tí a bá pàṣẹ fún ọ. Jọ̀wọ́ lo iṣẹ́ yìí nígbà tí o bá pàṣẹ fún ọ.

Iru waya Alloy ti ko ni igboro

Àwọn irinṣẹ́ tí a lè fi ṣe énámel ni wáyà alloy copper-nickel, Constantan wire, Manganin wire. Kama Wire, NiCr Alloy wire, FeCrAl Alloy wire àti bẹ́ẹ̀ bẹ́ẹ̀ lọ wáyà alloy.

Iru idabobo

| Orúkọ tí a fi àmì ìdábòbò ṣe | Ipele Ooru°C (Akoko iṣẹ 2000h) | Orúkọ Kóòdù | Kóòdù GB | ANSI. IRÚ |

| Waya onirin polyurethane | 130 | EUW | QA | MW75C |

| Waya ti a fi enamel ṣe pẹlu polyester | 155 | PEW | QZ | MW5C |

| Waya ti a fi enamel ṣe pẹlu polyester-imide | 180 | EIW | QZY | MW30C |

| Waya onípele méjì tí a fi enamel bo tí a fi polyester-imide àti polyamide-imide | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Waya onípele polyamide-imide | 220 | AIW | QXY | MW81C |

Àkóónú Kẹ́míkà, %

| Cu | Bi | Sb | As | Fe | Ni | Pb | S | Zn | Ìtọ́sọ́nà ROHS | |||

| Cd | Pb | Hg | Cr | |||||||||

| 99.90 | 0.001 | 0.002 | 0.002 | 0.005 | - | 0.005 | 0.005 | - | ND | ND | ND | ND |

Àwọn Ohun Ànímọ́ Ti Ara

| Ibùdó Yíyọ́ – Liquidus | 1083ºC |

| Ibùdó Yíyọ́ – Solidus | 1065ºC |

| Ìwọ̀n | 8.91 gm/cm3@ 20 ºC |

| Wíwúwo pàtó | 8.91 |

| Agbara Itanna | 1.71 mikrhm-cm @ 20 ºC |

| Ìlànà Ìmúdàgba Mọ̀nàmọ́ná** | 0.591 MegaSiemens/cm @ 20 ºC |

| Ìgbékalẹ̀ Ooru | 391.1 W/m ·oK ní 20 C |

| Isodipupo ti Imugboroosi Ooru | 16.9 ·10-6 fun iwọnC(20-100 ºC) |

| Isodipupo ti Imugboroosi Ooru | 17.3 ·10-6perºC(20-200 ºC) |

| Isodipupo ti Imugboroosi Ooru | 17.6·10-6perºC(20-300 ºC) |

| Agbara Ooru Kan pato | 393.5 J/kg ·oK ni 293 K |

| Modulu ti Irọra ninu Itẹlera | 117000 Mpa |

| Modulu ti Rigidity | 44130 Mpa |

Lilo ti Ejò foil

1) Awọn isun omi ina ati ina, awọn yipada

2) Awọn fireemu asiwaju

3) Àwọn asopọ̀ àti àwọn ọ̀pá ìyípo

3)Aaye PCB

4) Okùn ìbánisọ̀rọ̀, ìhámọ́ra okùn, Okùn fóònù alágbèéká

5) Ion batiri gbóògì lamination pẹlu PI film

6) Awọn ohun elo PCB collector (elektrode backing)

Àwọn ẹ̀ka ọjà

-

Foonu

-

Ìmeeli

-

Whatsapp

-

WeChat

Judi

150 0000 2421

-

Òkè