Kaabo si awọn oju opo wẹẹbu wa!

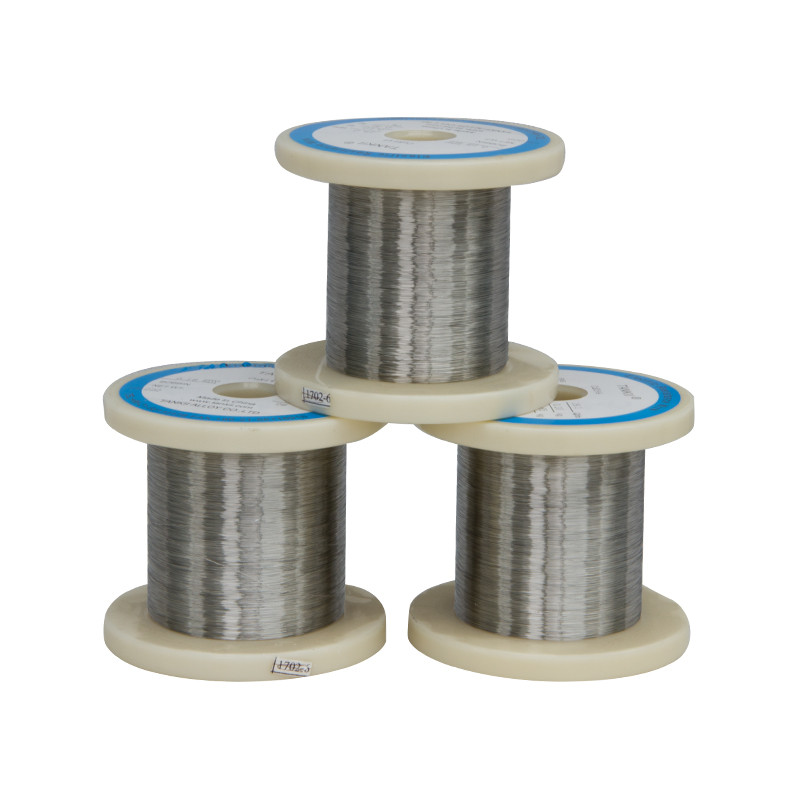

1j76 Ni76Cr2Cu5 Wáyà Alloys Aláwọ̀ Rírọ pẹ̀lú Ìgbésí Ayé Àkọ́kọ́ Gíga

Àkójọpọ̀ déédé%

| Ni | 75~76.5 | Fe | Bál. | Mn | 0.3~0.6 | Si | 0.15~0.3 |

| Mo | - | Cu | 4.8~5.2 | Cr | 1.8~2.2 | ||

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Awọn ohun-ini Imọ-ẹrọ deede

| Agbára ìfúnni | Agbara fifẹ | Gbigbọn |

| Mpa | Mpa | % |

| 980 | 1030 | 3-50 |

Àwọn ànímọ́ ara tó wọ́pọ̀

| Ìwọ̀n (g/cm3) | 8.6 |

| Agbara itanna ni 20ºC (Om*mm2/m) | 0.55 |

| Isodipupo ti imugboroosi laini (20ºC~ 200ºC)X10-6/ºC | 10.3~11.5 |

| Ìwọ̀n ìṣàkójọpọ̀ magnetostriction λθ/ 10-6 | 2.4 |

| Àmì Curie Tc/ºC | 400 |

Àwọn ohun ìní oofa ti àwọn alloys pẹ̀lú agbára gíga nínú àwọn pápá aláìlera | |||||||

| 1J76 | Ìfarabalẹ̀ àkọ́kọ́ | Gbigbe agbara to ga julọ | Ìfàgbára-ẹni-nípa | Ìwọ̀n ìfàsẹ́yìn oofa | |||

| Ìlà/àwo tí a ti yípo. Sisanra, mm | μ0.08/ (mH/m) | μm/ (mH/m) | Hc/ (A/m) | BS/T | |||

| ≥ | ≤ | ||||||

| 0.01 mm | 17.5 | 87.5 | 5.6 | 0.75 | |||

| 0.1~0.19 mm | 25.0 | 162.5 | 2.4 | ||||

| 0.2~0.34 mm | 28.0 | 225.0 | 1.6 | ||||

| 0.35~1.0 mm | 30.0 | 250.0 | 1.6 | ||||

| 1.1~2.5 mm | 27.5 | 225.0 | 1.6 | ||||

| 2.6~3.0 mm | 26.3 | 187.5 | 2.0 | ||||

| wáyà tí a fà mọ́ra tí ó tutù | |||||||

| 0.1 mm | 6.3 | 50 | 6.4 | ||||

| Ọtí | |||||||

| 8-100 mm | 25 | 100 | 3.2 | ||||

| Ipo itọju ooru 1J76 | |

| Àwọn ohun èlò ìròyìn tó ń fa ìfàsẹ́yìn | Fi ìfúnpá pamọ́ pẹ̀lú ìfúnpá tó kù tí kò ga ju 0.1Pa lọ, hydrogen pẹ̀lú ojú ìrísí tí kò ga ju 40ºC lọ. |

| Iwọn otutu ati oṣuwọn ti alapapo | 1100~1150ºC |

| Àkókò ìdádúró | 3~6 |

| Oṣuwọn itutu | Pẹ̀lú 100 ~ 200 ºC/h, a ti tutù sí 600 ºC, a sì ti tutù kíákíá sí 300ºC |

Kọ ifiranṣẹ rẹ si ibi ki o fi ranṣẹ si wa

Àwọn ẹ̀ka ọjà

-

Foonu

-

Ìmeeli

-

Whatsapp

-

WeChat

Judi

150 0000 2421

-

Òkè